Vaccum Infusion Process

Vacuum Infusion Process

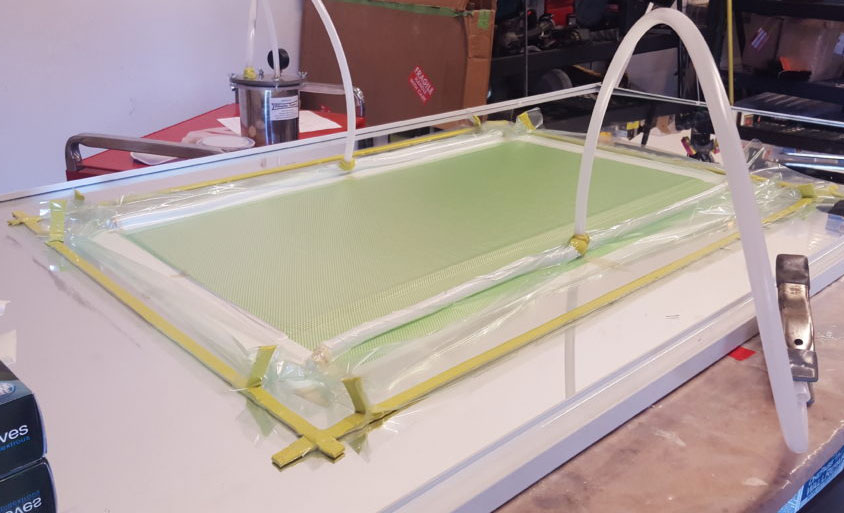

Vacuum Infusion Process (VIP) is a technique that uses vacuum pressure to drive resin into a laminate. Materials are laid dry into the mold and the vacuum is applied before resin is introduced. Once a complete vacuum is achieved, resin is literally sucked into the laminate via carefully placed tubing.

The process is highly controllable, due to it being governed by the principles of D’Arcy’s Law.

There are only three variables affecting the flow of the resin:

- Permeability of the laminate

- Viscosity of the resin

- Pressure differential in the cavity in relation to atmospheric pressure.

Benefits of Vacuum Infusion

- Better fiber-to-resin ratio

- Less wasted resin

- Very consistent resin usage

- Unlimited set-up time

- Cleaner

The two main drawbacks of VIP

slower cycle times and higher consumable costs